-

221

-

153

-

141

-

132

-

131

Development of a Test Method for the Estimation of SBR-BR Blend Ratio in Tyre Tread Formulation and Validating It through Robust Statistical Tools

DOI:

https://doi.org/10.30564/opmr.v5i1.5368Abstract

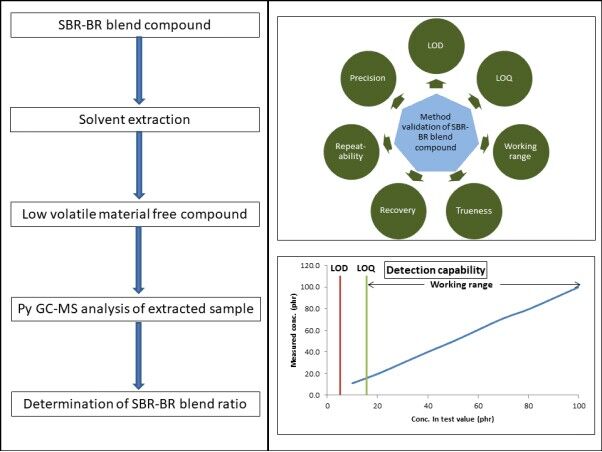

Blends of synthetic rubbers are widely used by rubber product manufacturing industries depending on the end use and product application. The estimation of individual rubber in blends is an important aspect to characterise the correctness of the mixing process. In tyre industry, Styrene butadiene rubber/Polybutadiene rubber (SBR/BR) blend is commonly used to achieve different performance properties, particularly for passenger car tyre. Out of the different quantitative analysis techniques to characterise the blend, one of the widely used techniques Gas Chromatography-Mass Spectrometry (GC-MS) has been used to develop and later validate a method to quantify the SBR/BR blend ratio. Through this GC-MS technique detection capability is measured, with a minimum limit of detection (LOD) of 5.17% and a limit of quantification (LOQ) of 15.67% Styrene butadiene rubber (SBR) in an SBR-BR vulcanizate. It is observed that the bias percentage is highest in case of a lower SBR content sample, i.e. 11.1% while in the case of other sets, it is varying from (–)1.4% to (+)1.5%. During the recovery study, it is observed that with increasing SBR content, recovery is also improving. All requirements for a successful method validation: Accuracy, precision, selectivity, detection capability, calibration range and robustness have been carried out in this entire work.

Keywords:

Method validation; Synthetic rubber (Styrene butadiene rubber/Polybutadiene-rubber) blend; Gas chromatography/Mass spectrometry; Analytical technique; Quantitative analysisReferences

[1] Rodgers, B., Halasa, A., 2011. Compounding and processing of rubber/rubber blends. Encyclopedia of polymer blends. Wiley: New York. pp.163-206. DOI: https://doi.org/10.1002/9783527805242.ch4

[2] Kaliyathan, A.V., Varghese, K.M., Nair, A.S., et al., 2020. Rubber-rubber blends: A critical review. Progress in Rubber, Plastics and Recycling Technology, 36(3), 196-242. DOI: https://doi.org/10.1177/1477760619895002

[3] Mensah, B., Agyei-Tuffour, B., Nyankson, E., et al., 2018. Preparation and characterization of rubber blends for industrial tire tread fabrication. International Journal of Polymer Science. 2473286. DOI: https://doi.org/10.1155/2018/2473286

[4] Arayapranee, W., 2012. Abrasion resistance of materials. IntechOpen: London. DOI: https://doi.org/10.5772/30556

[5] Chiu, H.T., Tsai, P.A., 2006. Aging and mechanical properties of NR/BR blends. Journal of Materials Engineering and Performance. 15, 88-94. DOI: https://doi.org/10.1361/105994906X83448

[6] Movahed, S.O., Ansarifar, A., Song, M., 2009. Effect of silanized silica nanofiller on tack and green strength of selected filled rubbers. Polymer International. 58(4), 424-429. DOI: https://doi.org/10.1002/pi.2554

[7] Stoček, R., Ghosh, P., Machu, A., et al., 2020. Fatigue crack growth vs. chip and cut wear of NR and NR/SBR blend-based rubber compounds. Fatigue Crack Growth in Rubber Materials: Experiments and Modelling. 286, 225-244. DOI: https://doi.org/10.1007/12_2020_67

[8] Sae-Oui, P., Suchiva, K., Sirisinha, C., et al., 2017. Effects of blend ratio and SBR type on properties of carbon black-filled and silica-filled SBR/BR tire tread compounds, Advances in Materials Science and Engineering. 2476101. DOI: https://doi.org/10.1155/2017/2476101

[9] Agulló, N., Borrós, S., 2002. Qualitative and quantitative determination of the polymer content in rubber formulations. Journal of Thermal Analysis and Calorimetry. 67, 513-522. DOI: https://doi.org/10.1023/A

[10] Fernández-Berridi, M.J., González, N., Mugica, A., et al., 2006. Pyrolysis-FTIR and TGA techniques as tools in the characterization of blends of natural rubber and SBR. Thermochimica Acta. 444, 65-70. DOI: https://doi.org/10.1016/j.tca.2006.02.027

[11] Schwenker, R.F., Garn, P.D., 1969. Thermal analysis: Instrumentation, organic materials, and polymers. Academic Press: Worcester.

[12] Menis, O., 1970. U.S.N.B. of Standards, A.S. Status of Thermal Analysis [Internet]. Proceedings of a Symposium on the Current Status of Thermal Analysis. Available from: https://www.govinfo.gov/content/pkg/GOVPUB-C13-32862acc60d26a1a0258981a96243319/pdf/GOVPUB-C13-32862acc60d26a1a0258981a96243319.pdf

[13] Lee, Y.S., Lee, W.K., Cho, S.G., et al., 2007. Quantitative analysis of unknown compositions in ternary polymer blends: A model study on NR/SBR/BR system. Journal of Analytical and Applied Pyrolysis. 78, 85-94. DOI: https://doi.org/10.1016/j.jaap.2006.05.001

[14] Azevedo, J.B., Murakami, L.M.S., Ferreira, A.C., et al., 2018. Quantification by FT-IR (UATR/NIRA) of NBR/SBR blends. Polimeros. 28, 440-449. DOI: https://doi.org/10.1590/0104-1428.00918

[15] Mashimo, S., Hoshikawas, K., Okubo, N., et al., 1968. The analysis of rubber by pyrolysis and temperature programmed gas chromatography with porapak column. Nippon Gomu Kyokaishi. 41, 499-504. DOI: https://doi.org/10.2324/gomu.41.499

[16] Ghebremeskel, G.N., Sekinger, J.K., Hoffpauir, J.L., et al., 1996. A study of the thermal degradation products of Styrene-Butadiene type rubber by Pyrolysis/GC/MS. Rubber Chemistry and Technology. 69, 874-884. DOI: https://doi.org/10.5254/1.3538409

[17] Choi, S.S., Kwon, H.M., 2014. Analytical method for determination of butadiene and styrene contents of styrene-butadiene rubber vulcanizates without pretreatment using pyrolysis-gas chromatography/mass spectrometry. Polymer Testing. 38, 87-90. DOI: https://doi.org/10.1016/j.polymertesting.2014.07.005

[18] Terrill, E.R., Barbur, A.C., Maffei, M.J., 2008. Tire Innerliner Analysis for NHTSA Tire Aging Test Development Project [Internet]. Available from: https://www.ardl.com/sites/default/files/docs/papers/Ed/ACS/2._tire_innerliner_analysis_for_nhtsa_tire_aging_-_terrill_barbur_maffei.pdf

[19] Magnusson, B., Örnemark, U. (editors), 2014. The Fitness for Purpose of Analytical Methods—A Laboratory Guide to Method Validation and Related Topics [Internet]. Available from: https://www.eurachem.org

[20] Miller, J.N., 1991. Basic statistical methods for analytical chemistry. Part 2. Calibration and regression methods. A review. Analyst. 116, 3-14. DOI: https://doi.org/10.1039/AN9911600003

[21] Taverniers, I., Van Bockstaele, E., De Loose, M., 2007. Analytical method validation and quality assurance. Wiley: New York. pp. 743-789. DOI: https://doi.org/10.1002/9780470259832.ch23

[22] Read, S., 2017. ISO/IEC 17025: 2017 General Requirements for the Competence of Testing and Calibration Laboratories [Internet]. Available from: https://www.iso.org/files/live/sites/isoorg/files/store/en/PUB100424.pdf

[23] ISO 1407: 2011. Rubber-Determination of Solvent Extract [Internet]. Available from: https://www.iso.org/standard/51794.html

[24] Kusch, P., Obst, V., Schroeder-Obst, D., et al., 2013. Application of pyrolysis-gas chromatography/mass spectrometry for the identification of polymeric materials in failure analysis in the automotive industry. Engineering Failure Analysis. 35, 114-124. DOI: https://doi.org/10.1016/j.engfailanal.2012.12.005

[25] Kusch, P., Schroeder-Obst, D., Obst, V., et al., 2016. Handbook of materials failure analysis with case studies from the chemicals, concrete and power industries. Butterworth-Heinemann: London. pp. 441-469. DOI: https://doi.org/10.1016/B978-0-08-100116-5.00017-X

[26] Kusch, P., 2012. Pyrolysis-gas chromatography/mass spectrometry of polymeric materials. Advanced gas chromatography. IntechOpen: Rijeka. DOI: https://doi.org/10.5772/32323

[27] Armbruster, D.A., Pry, T., 2008. Limit of blank, limit of detection and limit of quantitation. The Clinical Biochemist Reviews. 29(Suppl 1), S49-S52.

[28] Shrivastava, A., Gupta, V., 2011. Methods for the determination of limit of detection and limit of quantitation of the analytical methods. Chronicles of Young Scientists. 2, 21-25. DOI: https://doi.org/10.4103/2229-5186.79345

Downloads

How to Cite

Issue

Article Type

License

Copyright © 2023 Tirthankar Bhandary, Hirak Satpathi, Aratrika Banerjee, Koushik Pal, Abhijit Pal, Barun Kumar Samui, Saikat Dasgupta, Rabindra Mukhopadhyay

This is an open access article under the Creative Commons Attribution-NonCommercial 4.0 International (CC BY-NC 4.0) License.

Tirthankar Bhandary

Tirthankar Bhandary